Main Difference

The main difference between Polystyrene and Polyester is that the Polystyrene is a polymer and Polyester is a category of polymers.

-

Polystyrene

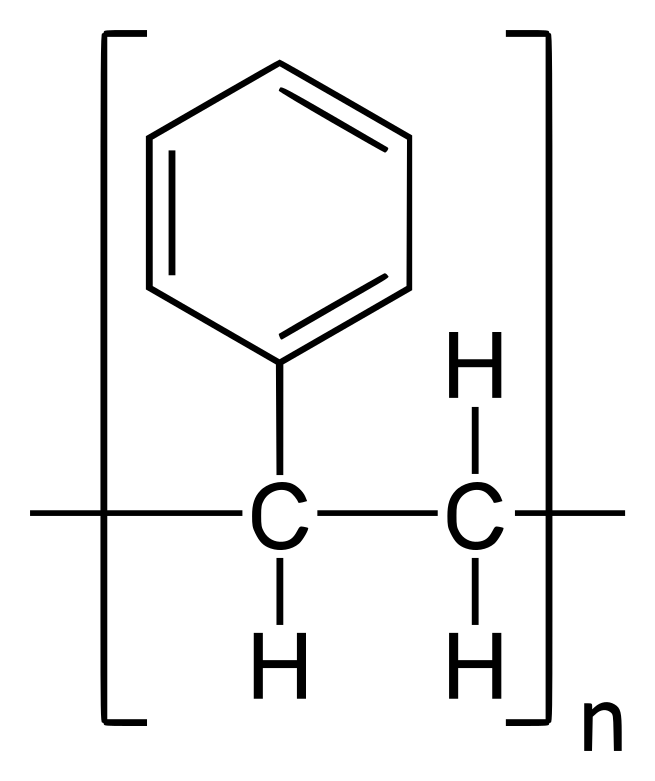

Polystyrene (PS) is a synthetic aromatic hydrocarbon polymer made from the monomer styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and rather brittle. It is an inexpensive resin per unit weight. It is a rather poor barrier to oxygen and water vapour and has a relatively low melting point. Polystyrene is one of the most widely used plastics, the scale of its production being several million tonnes per year. Polystyrene can be naturally transparent, but can be coloured with colourants. Uses include protective packaging (such as packing peanuts and CD and DVD cases), containers (such as “clamshells”), lids, bottles, trays, tumblers, disposable cutlery and in the making of models.

As a thermoplastic polymer, polystyrene is in a solid (glassy) state at room temperature but flows if heated above about 100 °C, its glass transition temperature. It becomes rigid again when cooled. This temperature behaviour is exploited for extrusion (as in Styrofoam) and also for molding and vacuum forming, since it can be cast into molds with fine detail.

Polystyrene is slow to biodegrade and is therefore a focus of controversy among environmentalists. It is increasingly abundant as a form of litter in the outdoor environment, particularly along shores and waterways, especially in its foam form, and also in increasing quantities in the Pacific Ocean.

-

Polyester

Polyester is a category of polymers that contain the ester functional group in their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include naturally occurring chemicals, such as in the cutin of plant cuticles, as well as synthetics such as polybutyrate. Natural polyesters and a few synthetic ones are biodegradable, but most synthetic polyesters are not. The material is used extensively in clothing.

Depending on the chemical structure, polyester can be a thermoplastic or thermoset. There are also polyester resins cured by hardeners; however, the most common polyesters are thermoplastics. Examples of thermoset polyesters include the Desmophen brand from Bayer. The OH group is reacted with an Isocyanate functional compound in a 2 component system producing coatings which may optionally be pigmented.

Fabrics woven or knitted from polyester thread or yarn are used extensively in apparel and home furnishings, from shirts and pants to jackets and hats, bed sheets, blankets, upholstered furniture and computer mouse mats. Industrial polyester fibers, yarns and ropes are used in car tire reinforcements, fabrics for conveyor belts, safety belts, coated fabrics and plastic reinforcements with high-energy absorption. Polyester fiber is used as cushioning and insulating material in pillows, comforters and upholstery padding. Polyester fabrics are highly stain-resistant—in fact, the only class of dyes which can be used to alter the color of polyester fabric are what are known as disperse dyes.Polyester fibers are sometimes spun together with natural fibers to produce a cloth with blended properties. Cotton-polyester blends (polycotton) can be strong, wrinkle and tear-resistant, and reduce shrinking. Synthetic fibers using polyester have high water, wind and environmental resistance compared to plant-derived fibers. They are less fire resistant and can melt when ignited.Polyester blends have been renamed so as to suggest their similarity or even superiority to natural fibers (for example, China silk, which is a term in the textiles industry for a 100% polyester fiber woven to resemble the sheen and durability of insect-derived silk).

Polyesters are also used to make bottles, films, tarpaulin, canoes, liquid crystal displays, holograms, filters, dielectric film for capacitors, film insulation for wire and insulating tapes. Polyesters are widely used as a finish on high-quality wood products such as guitars, pianos and vehicle/yacht interiors. Thixotropic properties of spray-applicable polyesters make them ideal for use on open-grain timbers, as they can quickly fill wood grain, with a high-build film thickness per coat. Cured polyesters can be sanded and polished to a high-gloss, durable finish.

Liquid crystalline polyesters are among the first industrially used liquid crystal polymers. They are used for their mechanical properties and heat-resistance. These traits are also important in their application as an abradable seal in jet engines.

Natural polyesters could have a played a significant role in the origins of life. Long heterogeneous polyester chains are known to easily form in a one-pot reaction without catalyst under simple prebiotic conditions.

-

Polystyrene (noun)

A vinylic polymer of styrene, CH2CHphenyl.

-

Polystyrene (noun)

An alkane chain of benzene molecules, RCH2CHphenylR.

-

Polyester (noun)

Any polymer whose monomers are linked together by ester bonds

-

Polyester (noun)

A material or fabric made from polyester polymer

-

Polyester (adjective)

Of, or consisting of polyesters

-

Polyester (noun)

a synthetic resin in which the polymer units are linked by ester groups, used chiefly to make synthetic textile fibres.

-

Polyester (noun)

a fabric made from polyester fibre

“dresses in printed polyesters”

“swimwear in a range of fabrics including polyester and silk”