-

Pasteurization

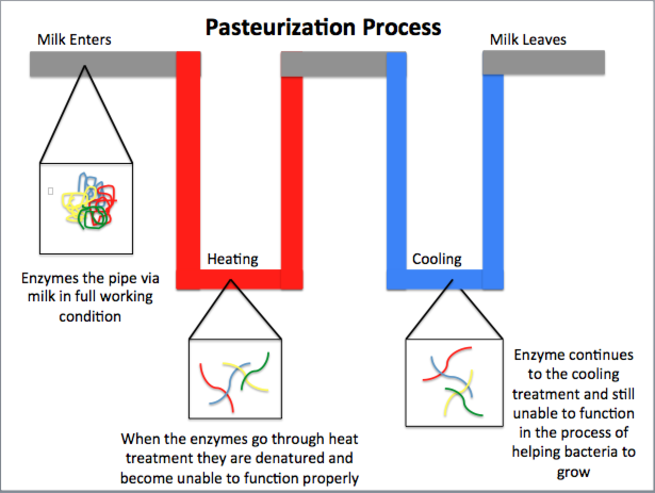

Pasteurization or pasteurisation is a process in which water and certain packaged and non-packaged foods (such as milk and fruit juice) are treated with mild heat, usually to less than 100 °C (212 °F), to eliminate pathogens and extend shelf life. The process is intended to destroy or deactivate organisms and enzymes that contribute to spoilage or risk of disease, including vegetative bacteria, but not bacterial spores. Since pasteurization is not sterilization, and does not kill spores, a second “double” pasteurization will extend the quality by killing spores that have germinated.

The process was named after the French microbiologist, Louis Pasteur, whose research in the 1880s demonstrated that thermal processing would inactivate unwanted microorganisms in wine. Spoilage enzymes are also inactivated during pasteurization. Today, pasteurization is used widely in the dairy industry and other food processing industries to achieve food preservation and food safety.Most liquid products are heat treated in a continuous system where heat can be applied using a plate heat exchanger or the direct or indirect use of hot water and steam. Due to the mild heat, there are minor changes to the nutritional quality and sensory characteristics of the treated foods. Pascalization or high pressure processing (HPP) and pulsed electric field (PEF) are non-thermal processes that are also used to pasteurize foods.

-

Tyndallization

Tyndallization is a process dating from the nineteenth century for sterilizing substances, usually food, named after its inventor, scientist John Tyndall, that can be used to kill heat-resistant endospores. Although considered old-fashioned, it is still occasionally used.

A simple and effective sterilizing method commonly used today is autoclaving: heating the substance being sterilized to 121 °C for 15 minutes in a pressured system. If autoclaving is not possible because of lack of equipment, or the need to sterilize something that will not withstand the higher temperature, unpressurized heating for a prolonged period at a temperature of up to 100 °C, the boiling point of water, may be used. The heat will kill the bacterial cells; however, bacterial spores capable of later germinating into bacterial cells may survive. Tyndallization can be used to destroy the spores.Tyndallization essentially consists of heating the substance to boiling point (or just a little below boiling point) and holding it there for 15 minutes, three days in succession. After each heating, the resting period will allow spores that have survived to germinate into bacterial cells; these cells will be killed by the next day’s heating. During the resting periods the substance being sterilized is kept in a moist environment at a warm room temperature, conducive to germination of the spores. When the environment is favourable for bacteria, it is conducive to the germination of cells from spores, and spores do not form from cells in this environment (see bacterial spores).

The Tyndallization process is usually effective in practice. But it is not considered totally reliable—some spores may survive and later germinate and multiply. It is not often used today, but is used for sterilizing some things that cannot withstand pressurized heating, such as plant seeds.